Automotive ERP: Streamlining Operations for a Smarter, More Efficient Industry

In today’s rapidly evolving automotive landscape, manufacturers and suppliers are grappling with unprecedented challenges that demand innovative solutions. The industry is under pressure to enhance operational efficiency, streamline production, manage extensive supply chains, and ensure compliance with increasingly stringent regulations. As consumer expectations shift towards faster deliveries, personalized options, and sustainable manufacturing, companies must rethink traditional workflows to remain competitive.

To navigate these complexities, automotive ERP (Enterprise Resource Planning) systems have become an essential tool for modern automotive businesses. These comprehensive software solutions unify and optimize critical business functions—including inventory management, production planning, financial tracking, and customer relationship management—under a single, integrated platform. With real-time data visibility and process automation, automotive ERP empowers businesses to make informed decisions, minimize inefficiencies, and scale effectively.

However, the successful implementation of an automotive ERP system requires strategic planning, customization, and expert guidance. This is where partnering with a reputable software development company becomes invaluable. A tailored ERP solution ensures seamless integration with existing processes, reduces downtime, and maximizes return on investment, enabling businesses to stay ahead in an increasingly digital and data-driven industry.

The Growing Importance of Automotive ERP

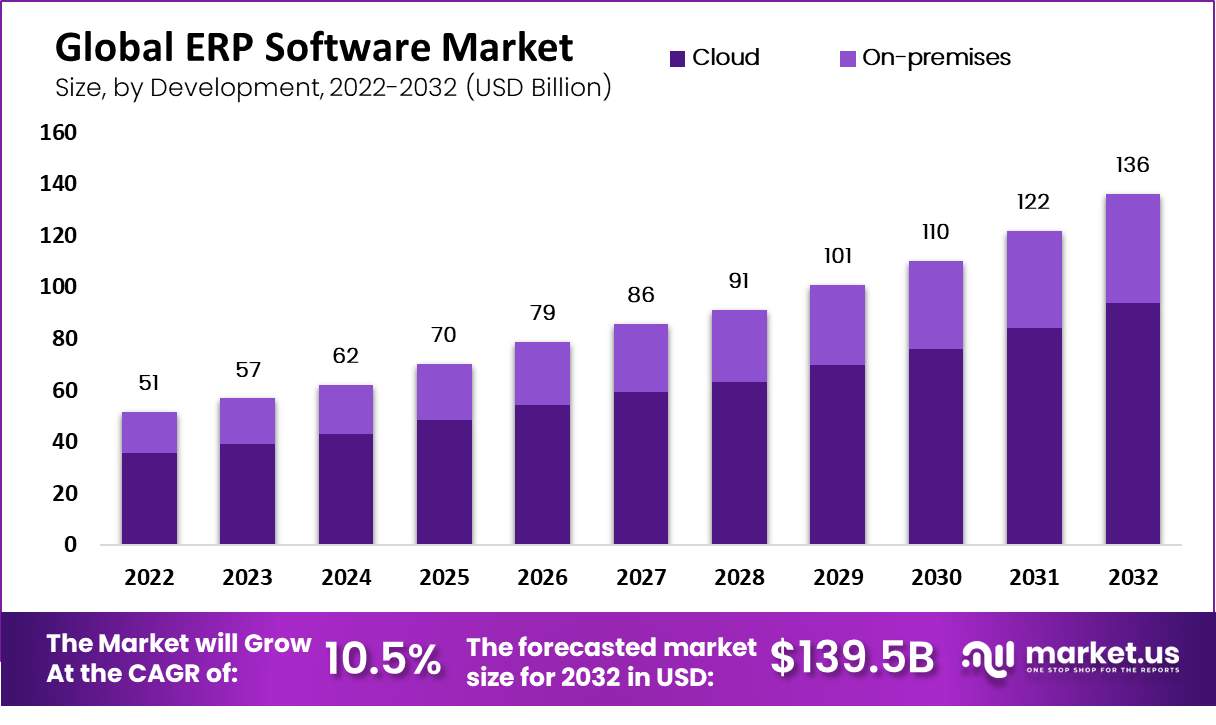

The demand for automotive ERP is growing rapidly, reflecting the industry’s increasing reliance on digital transformation. The global ERP software market is projected to surpass around USD 136.1 billion by 2032, with a compound annual growth rate (CAGR) of 7.1%. This surge highlights the necessity of ERP solutions in optimizing business operations, improving supply chain visibility, and enhancing overall efficiency across various industries—particularly in the automotive sector, where precision, agility, and compliance are paramount.

Image source: Globalnewswire

Key Benefits of Implementing Automotive ERP

The implementation of an automotive ERP system brings a multitude of advantages that extend beyond basic process automation. It transforms how manufacturers, suppliers, and distributors operate by enhancing efficiency, reducing costs, and improving overall business agility. Here’s a closer look at some of the key benefits:

Image source: Consulting Whiz

-

Enhanced Supply Chain Management: Modern automotive ERP systems provide real-time visibility into every stage of the supply chain, from procurement to final delivery. With automated tracking and predictive analytics, businesses can anticipate disruptions, optimize inventory levels, and coordinate more effectively with suppliers, ultimately reducing lead times and avoiding costly production delays.

-

Improved Production Efficiency: By integrating various manufacturing workflows—such as scheduling, quality control, and equipment maintenance—automotive ERP streamlines production operations. This integration minimizes downtime, eliminates redundant processes, and helps manufacturers achieve leaner, more cost-effective production cycles.

-

Regulatory Compliance and Risk Management: The automotive industry is subject to stringent safety and environmental regulations, making compliance a top priority. An automotive ERP system ensures that businesses adhere to evolving industry standards by automating compliance tracking, maintaining detailed audit trails, and generating reports for regulatory bodies. This reduces the risk of non-compliance penalties and enhances operational transparency.

-

Advanced Financial Management: Robust financial modules within automotive ERP solutions offer comprehensive budgeting, forecasting, and financial reporting capabilities. Businesses can track expenses in real-time, automate payroll and tax calculations, and ensure financial accuracy—critical for long-term profitability and sustainable growth.

-

Data-Driven Decision Making: In an increasingly competitive landscape, real-time data is a powerful asset. Automotive ERP centralizes data from various departments, providing decision-makers with up-to-date insights on sales performance, customer preferences, and operational bottlenecks. With predictive analytics and AI-driven reporting, companies can make proactive, strategic decisions that drive growth and innovation.

Have a Project Idea in Mind?

Get in touch with Savvycom’s experts for a free consultation. We’ll help you decide on next steps, explain how the development process is organized, and provide you with a free project estimate.

Cost Considerations in ERP Implementation

Understanding the cost of implementing an ERP system is essential for automotive businesses to make informed investment decisions. The total cost varies depending on factors such as company size, customization requirements, and deployment models (on-premise vs. cloud-based solutions).

Image source: Appinventiv

-

On average, small businesses spend approximately $7,143 per user over a five-year period, while mid-sized businesses may incur around $8,542 per user.

-

These costs typically include software licensing, implementation services, user training, system maintenance, and potential future upgrades.

-

Additionally, businesses should consider hidden costs such as data migration, integration with existing systems, and downtime during deployment.

While the initial investment may seem significant, the long-term benefits—such as improved efficiency, cost savings, and increased scalability—make automotive ERP a worthwhile investment for companies aiming to stay competitive in an evolving market.

ERP vs. ERM: Understanding the Distinction

As businesses strive for digital transformation, understanding the difference between ERP vs ERM is crucial for companies aiming to optimize operations while effectively managing risks.

Image source: Zendesk

-

ERP (Enterprise Resource Planning) is primarily designed to integrate and streamline core business functions such as supply chain management, production planning, finance, human resources, and customer relations. By centralizing data and automating workflows, ERP solutions enhance efficiency, reduce operational silos, and enable data-driven decision-making.

-

ERM (Enterprise Risk Management), on the other hand, focuses on identifying, assessing, and mitigating risks that could impact business continuity and compliance. ERM frameworks help organizations proactively address financial, strategic, regulatory, and cybersecurity risks.

While ERP and ERM serve distinct purposes, they are not mutually exclusive. An effective automotive ERP solution should incorporate risk management capabilities, such as compliance tracking, fraud detection, and cybersecurity measures, to ensure long-term sustainability. Companies that integrate ERM principles within their ERP systems gain a competitive edge by balancing operational efficiency with proactive risk mitigation.

Choosing the Right Automotive ERP Solution

Selecting the best ERP system for manufacturing is a critical decision that requires careful evaluation of multiple factors. A one-size-fits-all approach does not work for automotive businesses, as each company has unique needs, supply chain complexities, and production workflows. Here are key considerations for choosing the right automotive ERP solution:

-

Scalability & Flexibility: As businesses expand, their ERP system should be capable of growing alongside them. Whether it’s adding new production lines, entering new markets, or integrating with emerging technologies, a scalable automotive ERP ensures long-term adaptability.

-

Customization & Industry-Specific Features: A custom ERP software development approach allows manufacturers to tailor the system to their specific operational needs. Features such as real-time vehicle tracking, automated parts procurement, and regulatory compliance modules can significantly enhance efficiency.

-

User-Friendliness & Training Support: An ERP system must be intuitive for employees across different departments. Companies should prioritize solutions with user-friendly interfaces, role-based access, and comprehensive training programs to ensure smooth adoption.

-

Vendor Support & Integration Capabilities: The ERP provider’s track record, customer support services, and ability to integrate with existing automotive software (such as CAD tools, supply chain management platforms, and IoT systems) are critical for seamless deployment and ongoing maintenance.

By carefully assessing these factors, businesses can choose an automotive ERP solution that not only meets their current operational demands but also sets the foundation for future growth and innovation.

Looking For a Trusted Tech Partner?

We’ll help you decide on next steps, explain how the development process is organized, and provide you with a free project estimate.

The Role of Custom ERP Software Development

While off-the-shelf ERP solutions offer a broad range of functionalities, they often fall short in meeting the highly specific operational needs of automotive companies. Custom ERP software development allows businesses to design and implement a system that aligns perfectly with their workflows, supply chain logistics, and regulatory requirements.

By opting for a custom-built solution, companies can:

-

Enhance Integration & Compatibility: A tailor-made ERP system can seamlessly integrate with existing software tools such as product lifecycle management (PLM), customer relationship management (CRM), and IoT-enabled manufacturing systems, ensuring smooth data flow and eliminating silos.

-

Optimize Performance for Industry-Specific Needs: Automotive companies deal with complex inventory management, multi-tier supplier coordination, and just-in-time (JIT) production models. Custom ERP systems can be designed to optimize these critical operations.

-

Ensure Regulatory Compliance: The automotive sector must adhere to stringent regulations such as ISO/TS 16949, EPA standards, and safety compliance measures. A custom ERP system can include automated compliance tracking to mitigate risks.

-

Improve Scalability & Future Readiness: With the rapid evolution of electric vehicles (EVs), connected car ecosystems, and AI-driven automation, businesses need ERP systems that can evolve alongside these technological advancements. Custom development ensures adaptability without costly overhauls.

Investing in custom ERP software development is a strategic decision that enables automotive businesses to stay agile, competitive, and future-proof in an increasingly digitized industry.

Future Trends in Automotive ERP

The automotive sector is experiencing a paradigm shift driven by emerging technologies and changing consumer demands. Modern automotive ERP systems are rapidly evolving to accommodate these industry trends:

Image source: Deskera

-

Electric Vehicles (EV) & Battery Management Integration: With the global push for sustainability, automotive ERP is now integrating advanced battery lifecycle management, supply chain tracking for rare minerals, and compliance with green regulations.

-

Autonomous & Connected Vehicles: As self-driving technologies gain traction, ERP solutions must support AI-driven predictive maintenance, real-time vehicle diagnostics, and cybersecurity features to manage vehicle connectivity securely.

-

Cloud-Based & AI-Powered ERP: Cloud-based ERP solutions offer real-time data synchronization, remote accessibility, and reduced infrastructure costs, while AI-driven automation enhances predictive analytics, workflow automation, and smart decision-making.

-

Blockchain for Supply Chain Transparency: Many manufacturers are incorporating blockchain technology within ERP systems to ensure transparency, traceability, and fraud prevention across global supply chains.

By embracing these innovations, automotive ERP systems are set to revolutionize industry operations, enabling manufacturers and suppliers to remain agile in a highly competitive landscape.

Conclusion

Implementing an automotive ERP system is more than just an IT investment—it’s a strategic move that enhances operational efficiency, improves compliance, and fuels long-term growth. By carefully considering the cost of implementing an ERP system, assessing industry-specific needs, and integrating emerging technologies, automotive businesses can make informed decisions that position them for success in the evolving market.

Savvycom is a trusted software development company specializing in delivering innovative, high-performance ERP solutions tailored to industry-specific challenges. With a deep understanding of automotive digital transformation, Savvycom helps manufacturers, suppliers, and dealerships streamline their operations through cutting-edge technology and strategic software development. As the automotive industry embraces artificial intelligence, Savvycom also provides advanced AI for dealerships solutions, including intelligent inventory management, predictive customer analytics, and automated sales process optimization that enhance dealership performance and customer satisfaction.

Tech Consulting, End-to-End Product Development, Cloud & DevOps Service! Since 2009, Savvycom has been harnessing digital technologies for the benefit of businesses, mid and large enterprises, and startups across the variety of industries. We can help you to build high-quality software solutions and products as well as deliver a wide range of related professional services.

Savvycom is right where you need. Contact us now for further consultation:

- Phone: +84 24 3202 9222

- Hotline: +1 408 663 8600 (US); +612 8006 1349 (AUS); +84 32 675 2886 (VN)

- Email: [email protected]