At Savvycom, we specialize in providing end-to-end digital solutions tailored for Industry 4.0. Our AI-driven, IoT-enabled, and cloud-integrated manufacturing services enhance efficiency, automation, and real-time monitoring to help businesses thrive in a fast-evolving industrial landscape.

Manufacturing Solutions

What We Offer

As a manufacturing product development company, we specialize in a variety of areas to meet the needs of a wide range of industries, our offerings for manufacturing services are:

Robotic Process Automation

Work smarter, not harder – boost efficiency and precision with intelligent automation.

✓ Enhances manufacturing processes through automated solutions.

✓ Increases production efficiency by performing repetitive tasks faster and more consistently than humans.

✓ Reduces human errors through precise execution of automated tasks.

✓ Lowers operational costs by minimizing manual interventions.

Smart Manufacturing

Take full control of your production floor with automation, real-time monitoring, and data intelligence.

✓ Monitor and manage production operations in real-time for improved efficiency.

✓ Detect issues instantly and apply corrective actions to ensure product excellence.

✓ Leverage digital twins, predictive analytics, and IIoT to optimize performance.

✓ Reduce downtime with smart maintenance and real-time equipment monitoring.

✓ Streamline ERP, workforce, logistics, and factory operations for Industry 4.0 success.

Enterprise Resource Planning (ERP)

Break silos and streamline operations with a single, integrated platform for all your business processes.

✓ Integrates business processes across multiple departments for seamless operations.

✓ Provides real-time data access, improving efficiency and productivity.

✓ Enables accurate tracking, optimized workflows, and reduced operational costs.

✓ Enhances product quality control through better process management.

Reasons To Work With Us

AI-Driven Efficiency & Cost Reduction

Leverage AI, IoT, and automation for real-time monitoring, predictive maintenance, and process optimization – boost productivity while cutting costs.

Seamless System Integration

Effortlessly connect with ERP, MES, and industrial systems, ensuring a smooth transition with minimal disruption and maximum efficiency.

Data-Driven Decision Making

Harness the power of real-time analytics and AI insights to optimize operations, reduce downtime, and make smarter, faster business decisions.

Scalable & Future-Proof

Custom-built, flexible solutions that adapt and grow with your business, keeping you ahead in the era of smart manufacturing.

Security & Compliance First

We prioritize data security and regulatory compliance, ensuring your factory meets ISO, GDPR, and industry-specific standards while maintaining seamless operations.

Predictive Maintenance

We implement IoT-enabled predictive maintenance, reducing unexpected failures and extending equipment lifespan, lowering maintenance costs by up to 40%.

Ready to Elevate Your Manufacturing Business?

Our Development

Process at Savvycom

Here’s how we make it happen, from the napkin sketch to a full-fledged product.

01

Smart Data Collection & Connectivity

IoT sensors, RFID, and cloud-based SCADA, MES, and ERP integration enable real-time data tracking, optimizing decision-making and factory visibility.

02

AI-Powered Monitoring & Predictive Analytics

AI and Digital Twin technology provide real-time production insights, reducing downtime by 40% with predictive maintenance and process optimization.

03

Intelligent Automation & Robotics

Cobots, AGVs, and AI-driven CNC systems enhance production speed and precision, while automated quality inspection reduces defects and rework rates.

04

Smart Quality & Maintenance

AI-powered computer vision ensures real-time defect detection, and predictive maintenance prevents failures, increasing efficiency by 30%.

05

Logistics Optimization

AI-driven WMS, automated picking systems, and drone inspections optimize inventory, reducing material handling costs and improving supply chain efficiency.

06

Energy Efficiency & Cybersecurity

AI monitors energy consumption for sustainable manufacturing, while ISO 27001-compliant security measures protect data and ensure regulatory compliance.

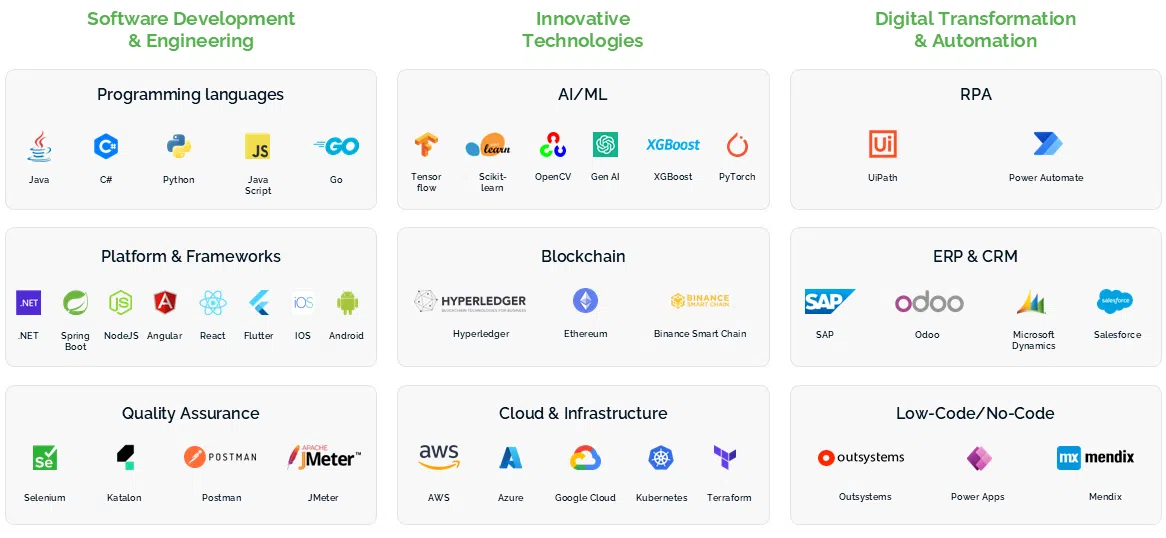

Technologies

Leveraging cutting-edge Software Development Methodologies and IT Outsourcing Models, we are equipped to architect and scale exceptional solutions from the ground up for our strategic partners and clients.

What Business Leaders Say About Savvycom

We deeply appreciate all feedbacks to improve the quality of our services!

Learn more about Savvycom – Software Outsourcing Company

Leverage the experience of Savvy Team to build your product